This view of the Owner's Manual contains the very latest information, which may vary slightly from the printed Owner's Manual originally provided with your vehicle. It may also describe content that is not on or operates differently on your vehicle. Please consider the Owner's Manual originally provided with your vehicle as the primary source of information for your vehicle.

The information contained in this publication was correct at the time of release.In the interest of continuous development, we reserve the right to change specifications, design or equipment at any time without notice or obligation.No part of this publication may be reproduced, transmitted, stored in a retrieval system or translated into any language in any form by any means without our written permission.Errors and omissions excepted.

Copyright © 2025 Ford Motor Company

Technical Specifications

Wheel Lug Nut Torque Specifications

WARNING:

When a wheel is installed, always remove any corrosion, dirt or foreign materials present on the mounting surfaces of the wheel or the surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the hub are secured so they do not interfere with the mounting surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while the vehicle is in motion, resulting in loss of control.

WARNING:

When a wheel is installed, always remove any corrosion, dirt or foreign materials present on the mounting surfaces of the wheel or the surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the hub are secured so they do not interfere with the mounting surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while the vehicle is in motion, resulting in loss of control. |

| Bolt size | lb.ft (Nm) |

|---|---|

| M14 x 1.5 | 165 lb.ft (224 Nm) |

*Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford recommended replacement fasteners.

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

It is important to follow the proper wheel mounting and lug nut torque procedures.

On all two-piece flat wheel nuts, apply one drop of motor oil between the flat washer and the nut. Do not apply motor oil to the wheel nut threads or the wheel stud threads.

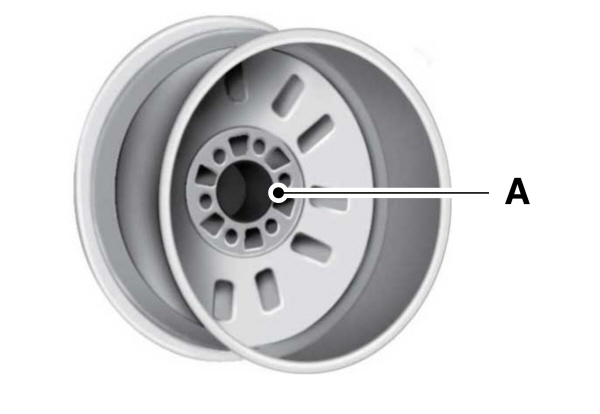

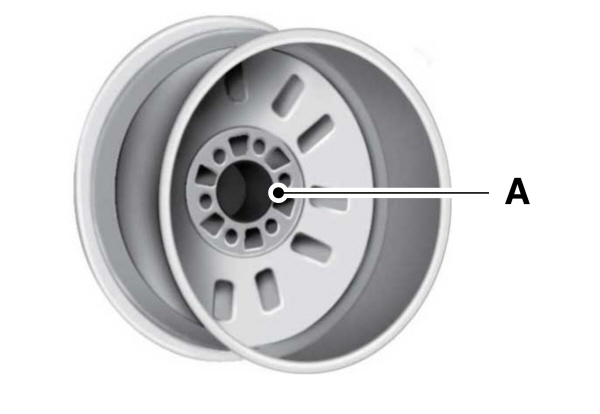

| A Inspect the wheel pilot hole and mounting surface prior to installation. Remove any visible corrosion or loose particles. |

- Please note that Ford will not respond to individual feedback.

- Please only provide detailed feedback regarding any inaccuracies in the content or any missing content in the Owner's Manual.

- Your feedback will be investigated, and any necessary changes will be updated in the online Owner's Manual.

- Please do not submit any vehicle related feedback. To submit feedback related to your vehicle, please click the link to find the correct contact information for your market.

Your input is valuable in helping us improve our Owner's Manual. Thank you for taking the time to provide your feedback.

North America

| Country | Phone | |

|---|---|---|

| United States | 1-800-392-3673 (FORD) | |

| Canada | 1-800-565-3673 (FORD) | |

| Mexico | 1-800-719-8466 | |

| Guam | 1-800-392-3673 (FORD) | |

| North Mariana Islands | apemcrc@ford.com | |

| Puerto Rico | (800) 841-3673 | prcac@ford.com |

| US Virgin Islands | (800) 841-3673 | prcac@ford.com |

IMG

| Country | Phone | |

|---|---|---|

| Algeria | nafcrc@ford.com | |

| Angola | ssacrc@ford.com | |

| Benin | ssacrc@ford.com | |

| Botswana | ssacrc@ford.com | |

| Burkina FASO | ssacrc@ford.com | |

| Burundi | ssacrc@ford.com | |

| Cameroon | ssacrc@ford.com | |

| Cape Verde | ssacrc@ford.com | |

| Central African Republic | ssacrc@ford.com | |

| Chad | ssacrc@ford.com | |

| Comoros | ssacrc@ford.com | |

| Dem Republic of Congo | ssacrc@ford.com | |

| Djibuti | ssacrc@ford.com | |

| Egypt | nafcrc@ford.com | |

| Equitorial Guinea | ssacrc@ford.com | |

| Eritrea | ssacrc@ford.com | |

| Ethiopia | ssacrc@ford.com | |

| Gabon | ssacrc@ford.com | |

| Gambia | ssacrc@ford.com | |

| Ghana | ssacrc@ford.com | |

| Guinea | ssacrc@ford.com | |

| Guinea-Bissau | ssacrc@ford.com | |

| Ivory Coast | ssacrc@ford.com | |

| Kenya | ssacrc@ford.com | |

| Liberia | ssacrc@ford.com | |

| Libya | nafcrc@ford.com | |

| Madagascar | ssacrc@ford.com | |

| Malawi | ssacrc@ford.com | |

| Mauritania | ssacrc@ford.com | |

| Mauritius | ssacrc@ford.com | |

| Morocco | nafcrc@ford.com | |

| Mozambique | ssacrc@ford.com | |

| Namibia | ssacrc@ford.com | |

| Niger | ssacrc@ford.com | |

| Nigeria | ssacrc@ford.com | |

| Republic of Congo | ssacrc@ford.com | |

| Rwanda | ssacrc@ford.com | |

| Sao Tome and Principe | ssacrc@ford.com | |

| Senegal | ssacrc@ford.com | |

| Sychelles | ssacrc@ford.com | |

| Sierra Leone | ssacrc@ford.com | |

| South Africa | 860011022 | fordcrc2@ford.com |

| South Sudan | ssacrc@ford.com | |

| Swaziland | ssacrc@ford.com | |

| Tanzania | ssacrc@ford.com | |

| Togo | ssacrc@ford.com | |

| Tunisia | nafcrc@ford.com | |

| Uganda | ssacrc@ford.com | |

| Zambia | ssacrc@ford.com | |

| Zimbabwe | ssacrc@ford.com | |

| American Somoa | apemcrc@ford.com | |

| Australia | (13 FORD) 13 3673 | foacust1@ford.com |

| Bangladesh | apemcrc@ford.com | |

| Bhutan | apemcrc@ford.com | |

| Brunei | apemcrc@ford.com | |

| Cambodia | apemcrc@ford.com | |

| Fiji | apemcrc@ford.com | |

| French Polynesia | apemcrc@ford.com | |

| India | apemcrc@ford.com | |

| Indonesia | apemcrc@ford.com | |

| Japan | apemcrc@ford.com | |

| Laos | apemcrc@ford.com | |

| Macao | apemcrc@ford.com | |

| Malaysia | apemcrc@ford.com | |

| Marshall Islands | apemcrc@ford.com | |

| Mongolia | apemcrc@ford.com | |

| Myanmar | apemcrc@ford.com | |

| Nepal | apemcrc@ford.com | |

| New Caledonia | apemcrc@ford.com | |

| New Zealand | 0800 367 369 (FORDNZ) | fnzcust@ford.com |

| Pakistan | apemcrc@ford.com | |

| Palau | apemcrc@ford.com | |

| Papua New Guinea | apemcrc@ford.com | |

| Philippines | 02-88669408 | emailus@ford.com |

| Singapore | apemcrc@ford.com | |

| South Korea | 82-2-1600-6003 | infokr1@ford.com |

| Sri Lanka | apemcrc@ford.com | |

| Tahiti | apemcrc@ford.com | |

| Thailand | 1383 | fordthai@ford.com |

| Timor Leste | apemcrc@ford.com | |

| Vanuatu | apemcrc@ford.com | |

| Vietnam | 1800588888 | fordvn@ford.com |

| Wallis and Futuna | apemcrc@ford.com | |

| Western Somoa | apemcrc@ford.com | |

| Afghanistan | menacac@ford.com | |

| Bahrain | menacac@ford.com | |

| Iraq | menacac@ford.com | |

| Israel | 08-9139995 | service1@kelekmotors.co.il |

| Jordan | menacac@ford.com | |

| Kuwait | 965 1 898900 | menacac@ford.com |

| Lebanon | menacac@ford.com | |

| Oman | menacac@ford.com | |

| Qatar | menacac@ford.com | |

| Saudi Arabia | 8008443673 | menacac@ford.com |

| Syria | menacac@ford.com | |

| United Arab Emirates | 80004441066 | menacac@ford.com |

| Yemen | menacac@ford.com |

Greater China

| Country | Phone | |

|---|---|---|

| China-Imported Vehicles | 400-690-1886 | |

| China-CAF | 951995 | |

| China-JMC | 400-003-1111 | |

| China-Lincoln | 400-988-6789 | |

| Taiwan | 0800-032100 | |

| Hong Kong | (852) 3768-4898 |

South America

| Country | Phone | |

|---|---|---|

| Argentina | 0800-888-3673 | |

| Bolivia | Contact Your Local Ford Distributor | |

| Brazil | 0800-703-3673 | central@ford.com |

| Chile | Contact Your Local Ford Distributor | |

| Colombia | Contact Your Local Ford Distributor | |

| Ecuador | Contact Your Local Ford Distributor | |

| French Guiana | Contact Your Local Ford Distributor | |

| Guyana | Contact Your Local Ford Distributor | |

| Paraguay | Contact Your Local Ford Distributor | |

| Peru | Contact Your Local Ford Distributor | |

| Suriname | Contact Your Local Ford Distributor | |

| Uruguay | Contact Your Local Ford Distributor | |

| Venezuela | Contact Your Local Ford Distributor |

Europe

| Country | Phone | |

|---|---|---|

| Albania | Contact Your Local Ford Distributor | |

| Andorra | Contact Your Local Ford Distributor | |

| Armenia | Contact Your Local Ford Distributor | |

| Austria | 01 20 609 2424 | kundenz@ford.com |

| Azerbaijan | Contact Your Local Ford Distributor | |

| Belarus | Contact Your Local Ford Distributor | |

| Belgium | 32 2 700 67 76 | custfobe@ford.com |

| Bosnia | Contact Your Local Ford Distributor | |

| Bulgaria | Contact Your Local Ford Distributor | |

| Croatia | Contact Your Local Ford Distributor | |

| Cyprus | Contact Your Local Ford Distributor | |

| Czech Republic | 800 3673 29 | zakaznik@ford.com |

| Denmark | 43 68 2000 | crcdk@ford.com |

| Estonia | 372 6710 060 | ford@infoauto.ee |

| Falkland Islands | Contact Your Local Ford Distributor | |

| Finland | 09 725 22022 | palvelut@ford.com |

| France | 0800 005 005 | crcfr@ford.com |

| Georgia | Contact Your Local Ford Distributor | |

| Germany | 0221 9999 2 999 | kunden@ford.com |

| Girbraltar | Contact Your Local Ford Distributor | |

| Greece | 216 900 88 99 | info11@ford.com |

| Hungary | +36 1 7777 555 | Contact Your Local Ford Distributor |

| Iceland | Contact Your Local Ford Distributor | |

| Ireland | 1800 771 199 | crcirela@ford.com |

| Italy | 800 22 44 33 | tu@ford.com |

| Kazakhstan | Contact Your Local Ford Distributor | |

| Latvia | +371 67303020 | |

| Liechtenstein | Contact Your Local Ford Distributor | |

| Lithuania | 370 5216 8226 | forduzklausos@inchcape.lt |

| Luxembourg | +352 248 71 800 | custfobe@ford.com |

| Macedonia | Contact Your Local Ford Distributor | |

| Malta | Contact Your Local Ford Distributor | |

| Moldova | Contact Your Local Ford Distributor | |

| Monaco | Contact Your Local Ford Distributor | |

| Montenegro | Contact Your Local Ford Distributor | |

| Netherlands | 70 7703 777 | klanten@ford.com |

| Norway | 47 66819739 | infonor@ford.com |

| Poland | 48 22 522 27 27 | kontakty@ford.com |

| Portugal | 800 210 373 | clientes@ford.com |

| Romania | 40 312298798 | crcro@ford.com |

| Russia | Contact Your Local Ford Distributor | |

| San Marino | Contact Your Local Ford Distributor | |

| Serbia | Contact Your Local Ford Distributor | |

| Serbia and Montenegro | Contact Your Local Ford Distributor | |

| Slovakia | Contact Your Local Ford Distributor | |

| Slovenia | Contact Your Local Ford Distributor | |

| South Georgia | Contact Your Local Ford Distributor | |

| Spain | 900 80 70 90 | crcspain@ford.com |

| Sweden | 08-593 66 333 | fordkund@ford.com |

| Switzerland | 044 511 14 45 | assistch@ford.com |

| Turkey | Contact Your Local Ford Distributor | |

| Ukraine | Contact Your Local Ford Distributor | |

| United Kingdom | 020 3564 4444 | UKCRC1@ford.com |

Caribbean and Central America

| Country | Phone | |

|---|---|---|

| Anguilla | (313) 594-4857 | expcac@ford.com |

| Antigua | (313) 594-4857 | expcac@ford.com |

| Aruba | (313) 594-4857 | expcac@ford.com |

| Bahamas | (313) 594-4857 | expcac@ford.com |

| Barbados | (313) 594-4857 | expcac@ford.com |

| Bermuda | (313) 594-4857 | expcac@ford.com |

| Bonaire and St. Eustatius | (313) 594-4857 | expcac@ford.com |

| Cayman Islands | (313) 594-4857 | expcac@ford.com |

| Curacao | (313) 594-4857 | expcac@ford.com |

| Dominica | (313) 594-4857 | expcac@ford.com |

| Dominican Republic | (313) 594-4857 | expcac@ford.com |

| Grenada | (313) 594-4857 | expcac@ford.com |

| Haiti | (313) 594-4857 | expcac@ford.com |

| Jamaica | (313) 594-4857 | expcac@ford.com |

| Martinique | (313) 594-4857 | expcac@ford.com |

| Montserrat | (313) 594-4857 | expcac@ford.com |

| St. Kitts and Nevis | (313) 594-4857 | expcac@ford.com |

| St. Lucia | (313) 594-4857 | expcac@ford.com |

| St. Martin | (313) 594-4857 | expcac@ford.com |

| St. Vincent and the Grenadines | (313) 594-4857 | expcac@ford.com |

| Trinidad and Tobago | (313) 594-4857 | expcac@ford.com |

| Turks and Caicos | (313) 594-4857 | expcac@ford.com |

| British Virgin Islands | (313) 594-4857 | expcac@ford.com |

| Netherlands Antilles | (313) 594-4857 | expcac@ford.com |

| Belize | (313) 594-4857 | expcac@ford.com |

| Costa Rica | (313) 594-4857 | expcac@ford.com |

| El Salvador | (313) 594-4857 | expcac@ford.com |

| Guatemala | (313) 594-4857 | expcac@ford.com |

| Honduras | (313) 594-4857 | expcac@ford.com |

| Nicaragua | (313) 594-4857 | expcac@ford.com |

| Panama | (313) 594-4857 | expcac@ford.com |